Blog

South Landing Eco-District Case Study

October 31, 2023

The following case study was published in Energy Intel Magazine’s 3rd Quarter 2023 publication and was coauthored by:

- Courtney Blodgett, Director of Strategy and Founding Team Member, Edo

- Easan Drury, Director of R&D, Edo

- James McNeill, Senior Machine Learning Engineer

- Mingu Kim, Machine Learning Engineer

Introduction

Machine learning, albeit a buzz phrase, is becoming of increasingly relevant for the built environment. For the first time, real-time data from advanced metering infrastructure (AMI) and building equipment data is available, enabled by the decreased cost of data gateways to extract data and the increased ability to generate simple yet accurate predictive models. The use of machine learning is allowing for the development of novel methods for cost-effective energy efficiency in commercial and industrial buildings.

Energy use in buildings accounts for approximately 40% of total annual global energy use and is dominated by heating, ventilation, and air-conditioning (HVAC) load. Building automation system (BAS) use in commercial buildings has grown significantly over the last two decades. However, BASs typically implement relatively simple rules-based controls that utilize existing conditions (e.g., current zone temperatures) for isolated equipment systems and HVAC zones in buildings. Since these narrowly scoped controls are unable to co-optimize across equipment systems and zones, and unable to anticipate future conditions in the building (e.g., impact of changing weather or occupancy), buildings are typically operated inefficiently.

Studies have shown that advanced HVAC controls can significantly reduce energy use, and associated carbon emissions, by up to 30% (Fernandez et al. 2017). Furthermore, these benefits can be realized at a low cost. Edo developed and tested advanced HVAC controls using a model predictive control (MPC) framework with machine learning models at the South Landing EcoDistrict (“South Landing”) in Spokane, Washington. This article provides insight into how our method was used to save energy and improve occupant comfort at South Landing.

MPC and Machine Learning Model

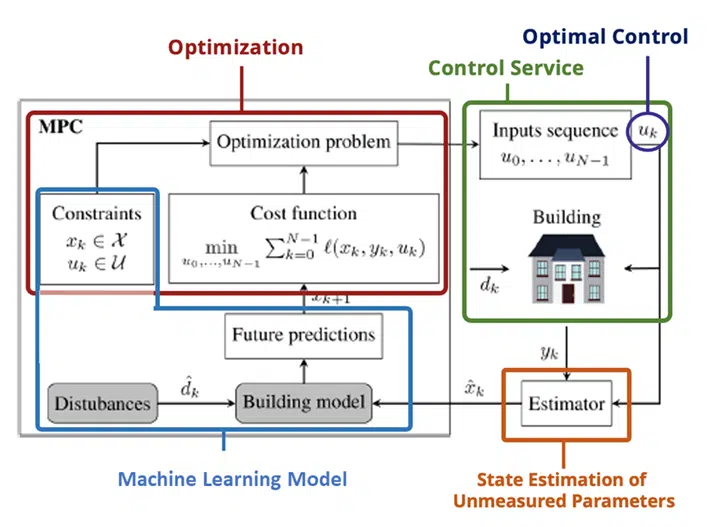

MPC is an advanced control method that optimizes the performance of a system. Edo’s MPC framework is designed to optimize HVAC controls of a building. Within the MPC framework, there are multiple reiterative steps (see Figure 1): forecasting, optimization, controls adjustments. Edo’s machine learning model is used to forecast the future behavior of each HVAC zone, based on changes in weather, occupancy, and HVAC controls. MPC then chooses HVAC control actions that optimize for energy savings and/or thermal comfort and these controls adjustments are implemented. The sequence is then simulated repeatedly while performing optimization of HVAC controls to determine which control sequences best reduce energy use while maintaining or improving occupant comfort.

Figure 1: Model predictive control framework. Source: Adapted from Drgona et al. (2020)

Addressing Adoption Barriers

MPC has not yet seen widespread adoption in buildings due to a variety of barriers. Edo recently completed a project funded by the Washington Clean Energy Fund 3 to address the following barriers to adoption:

- Availability of low-cost communication and control hardware to implement MPC.

- User-friendly, control-oriented, accurate, and computationally efficient building modeling.

- Automated design, tuning, and deployment of MPC.

- Privacy and cyber-security issues and the user trust.

For barrier 1, we developed a robustgateway(see Figure 2) that uses the BACnet communication protocol common in commercial buildings to:

- Stream data at a configurable interval from buildings to the cloud where data trends are archived, and optimization logic is run.

- Receive optimal control schedules from the cloud that are implemented on an edge control service to improve building performance.

Figure 2: Edo Data Gateway

For barrier 2, we developed anovel hybrid machine learning modelthat characterizes the impacts of weather, occupancy, and HVAC control signals on building performance.

For barrier 3, we developed a model deployment framework to pushmodels to the cloudwhere they are scheduled to re-train and generate optimal control signals daily, which are implemented as horizontally scalable serverless functions.

For barrier 4, we developed oursolution architecture with cybersecurityin mind from the bottom up. Specifically, we encrypt data at rest, developed a secure and encrypted data transmission framework, and run all optimization logic within a security group in the cloud. We also periodically conduct third-party penetration tests of the software applications running at the edge.

South Landing EcoDistrict Case Study

The South Landing EcoDistrict is a grid-interactive smart campus operated by Edo. The campus includes an all-electric central energy plant, two existing buildings totaling 200,000 square feet (see Figure 3), thermal hot water and phase change tanks, battery energy storage system, air source heat pumps, a heat recovery chiller, dedicated outdoor air system air-handling units, and 260 kilowatts of solar photovoltaics.

In the following sections, we will discuss the optimization logic and predictive models that we created for South Landing. We will describe how we implemented MPC at a zone level. Finally, we will detail how applying MPC at South Landing for 3 months impacted energy consumption and occupant comfort.

Figure 3: South Landing EcoDistrict

Optimization Logic

Edo developed a cloud-based control and optimization logic designed with a focus on cybersecurity. For South Landing, we developed an Optimal Start Algorithm (OSA). The OSA addresses the morning building warmup period which occurs during the transition from unoccupied to occupied periods during winter months. Optimization models are used todetermine optimal warm-up and cool-down periods, in addition to more complex setpoint optimization.

Edo’s cloud architecture includes multiple aggregated serverless functions that generateoptimal dispatch schedules for building equipment. These includebuilding models that generate forecastsof future energy use, zone temperatures, central plant operation, occupancy, and standard control variables. They also includeoptimization functions that generate control schedulesfor building equipment, andstate estimation functions that provide a feedback loop between predicted and actual building energy use. These serverless functions run at set intervals to calculate and update optimal controls, which are then persisted in cloud data stores and are pushed to the onsite gateway to be implemented by specific equipment systems.

Predictive Models

Machine learning models were used to predict the thermal responseof zones to external disturbances (e.g., outdoor air temperature, internal heat gains) to optimize the control of zone temperature setpoints. We applied grey-box models that utilize a hybrid machine learning framework that allows for accuracy and quick training of the model. The framework allows us to capture the effects of heat transfer through convection and conduction. We use machine learning to learn unmeasured state variables for the outer wall temperature, inner wall temperature, and inner zone temperature. We also allow for additions to the model to characterize the impacts of HVAC control, weather, occupancy, and other variables. We modeled the thermal response of building HVAC zones to external disturbances (e.g., outdoor air temperature, internal heat gains) to optimize the control of zone temperature setpoints.

Zone Level Optimization

MPC allowed for our data-driven, machine learning model to be implemented at a zone level at South Landing. MPC predicted the future behavior of each HVAC zone and chose control actions that optimized for energy savings and/or thermal comfort.

The grey-box model forecasts zone air temperatures with the following inputs:

- Preceding 24 hours of zone air temperatures

- Current and forecasted outside air temperature

- Current and forecasted heating setpoints

- Damper command.

With the above inputs, we then created a second ML model that forecasts building electricity load togenerate a feedback loop between controls and electricity load. Combined, this allows us to use zone temperature setpoints and building load as parameters togenerate future optimal control schedules.

We implemented only the first time interval, or timestep, of these optimal controls, and then iteratively rerun the optimization for every timestep. Multiple timesteps needed to be solved for in the optimization step to get the optimal control trajectory over time. We implemented only the first timestep to minimize the impact of error in our forecasting models. We ran this process iteratively to generate optimal control schedules over time.

Results

Our MPC framework made South Landing more comfortable while using less energy. The performance of the Optimal Start Algorithm was evaluated by comparing the optimal start cases with the historical base cases, allowing for a determination of the energy savings and comfort improvements.

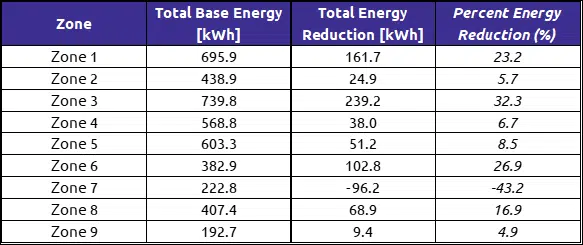

Table 1 shows the energy and demand reduction after optimal start is applied on 9 zones from 12/01/22 to 02/28/23. We find energy reductions in all but one zone. The energy reductions ranged from5-32%during the 3 months. We saw an increase in energy consumption in zone 7, where the algorithm increased energy use to improve occupant comfort.

Table 1: Energy reduction for individual zones by optimal start algorithm

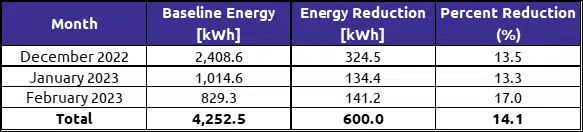

Table 2 shows the average energy reduction across all zones for the study period. In general, we saw about a14% reduction in energy used during the morning warmup period. We found that deeper energy savings can occur by allowing more significant zone temperature deviations from the set temperature band (70F -75F). Conversely, we can achieve smaller energy savings by prioritizing occupant comfort.

Table 2: Estimated energy reduction by month for optimal start algorithm

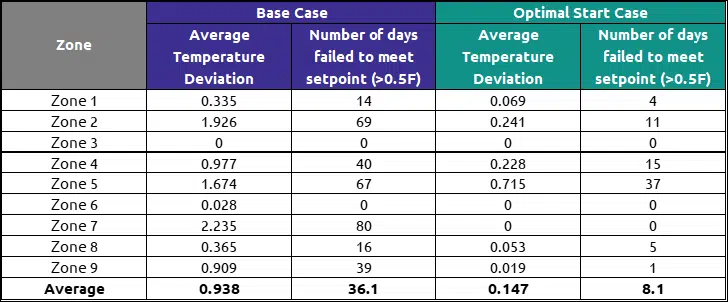

Table 3 shows comfort deviations in the study zones for the baseline period and after the application of MPC optimization. A deviation of zero represents zone temperatures staying within the set temperature band for all occupied hours, and a non-zero average deviation represents the average deviation outside of the temperature band for occupied hours. We found that we can significantly improve occupant comfort as seen by an average78% reduction in days where zone temperatures failed to meet setpointand by the average84% reduction in temperature deviation from setpoint. This is particularly true for zone 7 where the MPC algorithm increased energy use to improve occupant comfort. On average, we see generalimprovements in occupant comfortinaddition to the 14% average energy savings found during the morning warmup period.

Table 3: Difference in average zone temperature deviation from setpoint for base and optimal control cases

Conclusion

Improved occupant comfort and low-cost energy savings are two benefits of using an MPC framework in commercial and industrial buildings. Advanced HVAC controls can now be implemented on a larger scale as a strategy to reduce energy usage because of the decreased associated costs (e.g., data gateway, cloud computing).

References

Drgona, J., J. Arroyo, I. Figueroa, D. Blum, K. Arendt, D. Kim, E. Olle, J. Oravec, M. Wetter, D. Vrable, L. Helsen. (2020) All you need to know about model predictive control for buildings.Annual Reviews inControl, 50, 190-232.

Fernandez, N., Y. Xie, S. Katipamula, M. Zhao, W. Wang, C. Corbin (2017). Impacts of Commercial Building Controls on Energy Savings and Peak Load Reduction, Pacific Northwest National Lab, Richland, WA, PNNL-25985.